Hot water from thin air

A heatpump takes the heat from the surrounding air and uses it to heat the water in your pool.

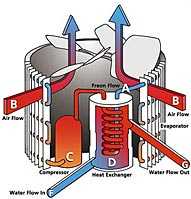

During heat pump operation, liquid freon from inside the unit is pumped through the system (A) and is turned into a heated gas. This happens when heat is taken from the surrounding air (B) as it is drawn through the evaporator by the fan. The compressor (C) receives this warmer gas and compresses it to a higher pressure, resulting in the freon reaching even higher temperatures. As the unit sends the heated gas through the heat exchanger, the gas gives up its heat to the surrounding water (D). The freon is then reverted to its liquid state which completes the cycle (A).

(F) The water, which is being forced through the heat exchanger (D) by your pool pump, is heated by three to five degrees as it passes through the heat exchanger. The water, now warmer, then flows back into your pool (G).

Heat Pump Technology IN ALL FORMS

Heat flows naturally from a higher to a lower temperature. Heat pumps, however, are able to force the heat flow in the other direction, using a relatively small amount of high quality drive energy (electricity, fuel, or high-temperature waste heat). Thus heat pumps can transfer heat from natural heat sources in the surroundings, such as the air, ground or water, or from man-made heat sources such as industrial or domestic waste, to a building or an industrial application. Heat pumps can also be used for cooling. Heat is then transferred in the opposite direction, from the application that is cooled, to surroundings at a higher temperature. Sometimes the excess heat from cooling is used to meet a simultaneous heat demand.

In order to transport heat from a heat source to a heat sink, external energy is needed to drive the heat pump. Theoretically, the total heat delivered by the heat pump is equal to the heat extracted from the heat source, plus the amount of drive energy supplied. Electrically-driven heat pumps for heating buildings typically supply 100 kWh of heat with just 20-40 kWh of electricity. Many industrial heat pumps can achieve even higher performance, and supply the same amount of heat with only 3-10 kWh of electricity.

Because heat pumps consume less primary energy than conventional heating systems, they are an important technology for reducing gas emissions that harm the environment, such as carbon dioxide (CO2), sulphur dioxide (SO2) and nitrogen oxides (NOx). However, the overall environmental impact of electric heat pumps depends very much on how the electricity is produced. Heat pumps driven by electricity from, for instance, hydropower or renewable energy reduce emissions more significantly than if the electricity is generated by coal, oil or gas-fired power plants.

The two main heat pump types

Almost all heat pumps currently in operation are either based on:

- a vapour compression, or on

- an absorption cycle.

These two principles will be briefly discussed in the following two sections.

Theoretically, heat pumping can be achieved by many more thermodynamic cycles and processes. These include Stirling and Vuilleumier cycles, single-phase cycles (e.g. with air, CO2 or noble gases), solid-vapour sorption systems, hybrid systems (notably combining the vapour compression and absorption cycle) and electromagnetic and acoustic processes. Some of these are entering the market or have reached technical maturity, and could become significant in the future.

Absorption Heat Pumps

Absorption heat pumps are thermally driven, which means that heat rather than mechanical energy is supplied to drive the cycle. Absorption heat pumps for space conditioning are often gas-fired, while industrial installations are usually driven by high-pressure steam or waste heat.

Absorption systems utilise the ability of liquids or salts to absorb the vapour of the working fluid. The most common working pairs for absorption systems are:

- water (working fluid) and lithium bromide (absorbent); and

- ammonia (working fluid) and water (absorbent).

In absorption systems, compression of the working fluid is achieved thermally in a solution circuit which consists of an absorber, a solution pump, a generator and an expansion valve as shown in Figure 3. Low-pressure vapour from the evaporator is absorbed in the absorbent. This process generates heat. The solution is pumped to high pressure and then enters the generator, where the working fluid is boiled off with an external heat supply at a high temperature. The working fluid (vapour) is condensed in the condenser while the absorbent is returned to the absorber via the expansion valve.

Heat is extracted from the heat source in the evaporator. Useful heat is given off at medium temperature in the condenser and in the absorber. In the generator high-temperature heat is supplied to run the process. A small amount of electricity may be needed to operate the solution pump.

For heat transformers, which through the same absorption processes can upgrade waste heat without requiring an external heat source, refer to the section on Heat pumps in industry.

Heat Pump Systems in Industry

Relatively few heat pumps are currently installed in industry. However, as environmental regulations become stricter, industrial heat pumps can become an important technology to reduce emissions, improve efficiency, and limit the use of ground water for cooling.

To ensure the sound application of heat pumps in industry, processes should be optimised and integrated. Through process integration improved energy efficiency is achieved by thermodynamically optimising total industrial processes. An important instrument for process integration is pinch analysis, a technology to characterise process heat streams and identify possibilities for heat recovery. Such possibilities may include improved heat exchanger networks, cogeneration and heat pumps. Pinch analysis is especially powerful for large, complex processes with multiple operations, and is an excellent instrument to identify sound heat pump opportunities.

Industrial applications show a great variation in the type of drive energy, heat pump size, operating conditions, heat sources and the type of application. The heat pump units are generally designed for a specific application, and are therefore unique.

The major types of industrial heat pumps are:

- Mechanical vapour recompression systems (MVRs), classified as open or semi-open heat pumps. In open systems, vapour from an industrial process is compressed to a higher pressure and thus a higher temperature, and condensed in the same process giving off heat. In semi-open systems, heat from the recompressed vapour is transferred to the process via a heat exchanger. Because one or two heat exchangers are eliminated (evaporator and/or condenser) and the temperature lift is generally small, the performance of MVR systems is high, with typical coefficients of performance (COPs) of 10 to 30. Current MVR systems work with heat-source temperatures from 70-80ºC, and deliver heat between 110 and 150ºC, in some cases up to 200ºC. Water is the most common ‘working fluid’ (i.e. recompressed process vapour), although other process vapours are also used, notably in the (petro-) chemical industry.

- Closed-cycle compression heat pumps are described in the section Heat pump technology. Currently applied working fluids limit the maximum output temperature to 120ºC.

- Absorption heat pumps (Type I) are not widely used in industrial applications. Some have been realised to recover heat from refuse incineration plants, notably in Sweden and Denmark. Current systems with water/lithium bromide as working pair achieve an output temperature of 100ºC and a temperature lift of 65ºC. The COP typically ranges from 1.2 to 1.4. The new generation of advanced absorption heat pump systems will have higher output temperatures (up to 260ºC) and higher temperature lifts.

- Heat transformers (Type II) have the same main components and working principle as absorption heat pumps. With a heat transformer waste heat can be upgraded, virtually without the use of external drive energy. Waste heat of a medium temperature (i.e. between the demand level and the environmental level) is supplied to the evaporator and generator. Useful heat of a higher temperature is given off in the absorber. All current systems use water and lithium bromide as working pair. These heat transformers can achieve a delivery temperatures up to 150ºC, typically with a lift of 50ºC. COPs under these conditions range from 0.45 to 0.48.

- Reverse Brayton-cycle heat pumps recover solvents from gases in many processes. Solvent loaden air is compressed, and then expanded. The air cools through the expansion, and the solvents condense and are recovered. Further expansion (with the associated additional cooling, condensation and solvent recovery) takes place in a turbine, which drives the compressor.

Applications

Industrial heat pumps are mainly used for:

- space heating;

- heating and cooling of process streams;

- water heating for washing, sanitation and cleaning;

- steam production;

- drying/dehumidification;

- evaporation;

- distillation;

- concentration.

When heat pumps are used in drying, evaporation and distillation processes, heat is recycled within the process. For space heating, heating of process streams and steam production, heat pumps utilise (waste) heat sources between 20ºC and 100ºC.

The most common waste heat streams in industry are cooling water, effluent, condensate, moisture, and condenser heat from refrigeration plants. Because of the fluctuation in waste heat supply, it can be necessary to use large storage tanks for accumulation to ensure stable operation of the heat pump.

Space heating:

Heat pumps can utilise conventional heat sources for heating of greenhouses and industrial buildings, or they can recover industrial waste heat that could not be used directly, and provide a low- to medium temperature heat that can be utilised internally or externally for space heating. Mainly electric closed-cycle compression heat pumps are used.

Process water heating and cooling:

Many industries need warm process water in the temperature range from 40-90ºC, and often have a significant hot water demand in the same temperature range for washing, sanitation and cleaning purposes. This can be met by heat pumps. Heat pumps can also be a part of an integrated system that provides both cooling and heating. Mainly electric closed-cycle compression heat pumps are installed, but a few absorption heat pumps and heat transformers are also in use.

Steam production:

Industry consumes vast amounts of low-, medium- and high-pressure steam in the temperature range from 100-200ºC. Steam is used directly in industrial processes, and for heat distribution. Current high temperature heat pumps can produce steam up to 150ºC (a heat pump prototype has achieved 300ºC). Both open and semi-open MVR systems, closed-cycle compression heat pumps, cascade (combination) systems and a few heat transformers are in operation.

Drying process:

Heat pumps are used extensively in industrial dehumidification and drying processes at low and moderate temperatures (maximum 100ºC). The main applications are drying of pulp and paper, various food products wood and lumber. Drying of temperature-sensitive products is also interesting. Heat pump dryers generally have high performance (COP 5-7), and often improve the quality of the dried products as compared with traditional drying methods. Because the drying is executed in a closed system, odours from the drying of food products etc. are reduced. Both closed-cycle compression heat pumps and MVR systems are used.

Evaporation and distillation processes:

Evaporation and distillation are energy-intensive processes, and most heat pumps are installed in these processes in the chemical and food industries. In evaporation processes the residue is the main product, while the vapour (distillate) is the main product in distillation processes. Most systems are open or semi-open MVRs, but closed-cycle compression heat pumps are also applied. Small temperature lifts result in high performance with COPs ranging from 6 to 30.