This is a typical pool pump. Note the parts of the pump. On the front of the pump you have a pump trap which has a basket that traps small debris and keeps it from clogging the pump. The pump body is where a “fanblade-like” impeller sucks in the water and forces it out the top of the pump. The pump motor is what drives the pump. The motor is air cooled while the pump is by its very nature water cooled.

This diagram illustrates how a pump operates. Water is drawn in the front of the pump, goes through the trap basket where the debris is strained out, and then is pulled into the impeller and thrust out the top of the pump. The front of the pump is referred to as the suction side and the top of the pump where the water comes out is referred to as the pressure side of the pump.

Pool Flow Rates

The first job of the pool pump is to circulate the pool water through the filter and back out to the pool. To do so, the pump must have a minimum flow rate in GPM (gallons per minute) that will allow it to move all the water through the filter within a given amount of time..

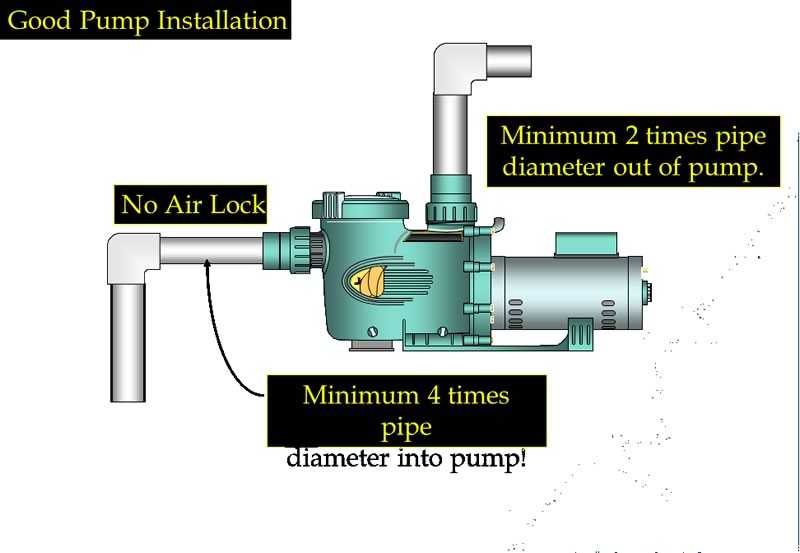

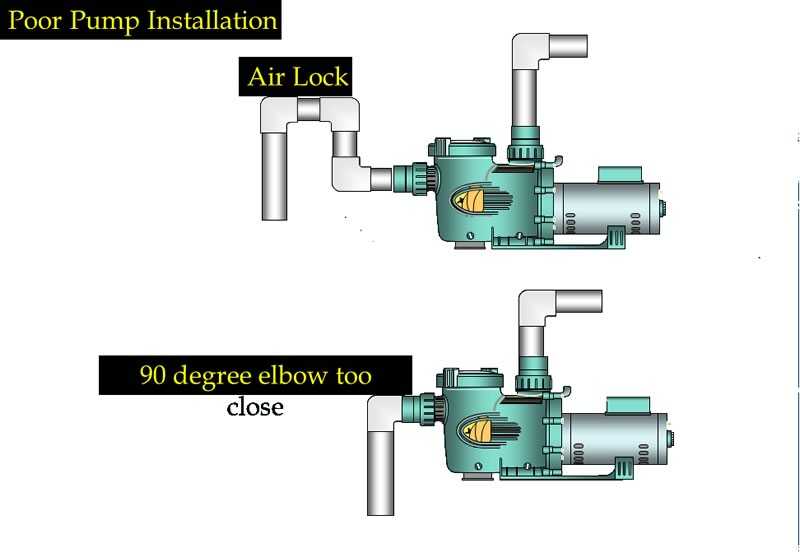

OK Now lets talk pump types and install methods..

LOW HEAD- Designed for high flow rates with very little resistance. Generally seen on large commercial pools or used on areas where the pump is close to the pool and at the same or below water level.

MEDIUM HEAD- Designed to be used where there is moderate resistance or where resistance dosen’t change. Generally used on with water features but can be used as circulation pumps. Most of pool pumps sold for basic pool purpose fits this type.

HIGH HEAD- Designed for use with high resistance or where resistance changes over time. Generally used as circulation pumps where the resistance changes over a period of time more than weeks as the filter gets dirty.